Your One-Stop Fabrication Shop: From Small Jobs To Major Projects

When it comes to fabrication, every project, big or small, demands a unique blend of skill, precision and innovation. Whether you're looking at a minor repair or a major construction, the right approach to fabrication can be the difference between an ordinary outcome and an exceptional one. In this blog, we're going to explore the multifaceted aspects of fabrication.

Exploring the Versatility of Fabrication Services

Fabrication services are important across various sectors, offering tailored solutions from building robust structures to precision automotive parts. Their versatility shines in the following:

- Construction: Providing important structural support in buildings, these services are important for safety and durability in architectural projects.

- Agriculture: Crafting machinery parts and storage solutions play a key role in enhancing the efficiency and productivity of agricultural operations.

- Automotive: Delivering precision-crafted custom parts, these services ensure optimal performance and reliability for vehicles.

The Art of Custom Fabrication: Meeting Unique Demands

Custom fabrication is a unique blend of creativity and functionality. It's about transforming a vision into a tangible reality. Let's delve into how this transformative process unfolds:

Understanding Your Vision

The journey begins with a deep understanding of your needs and ideas. It's about listening intently and grasping the essence of what you envision.

Design and Planning

Next, a dedicated team takes over, designing a solution that's not just a fit but a perfect match for your specifications. This stage is where your ideas start taking a concrete shape.

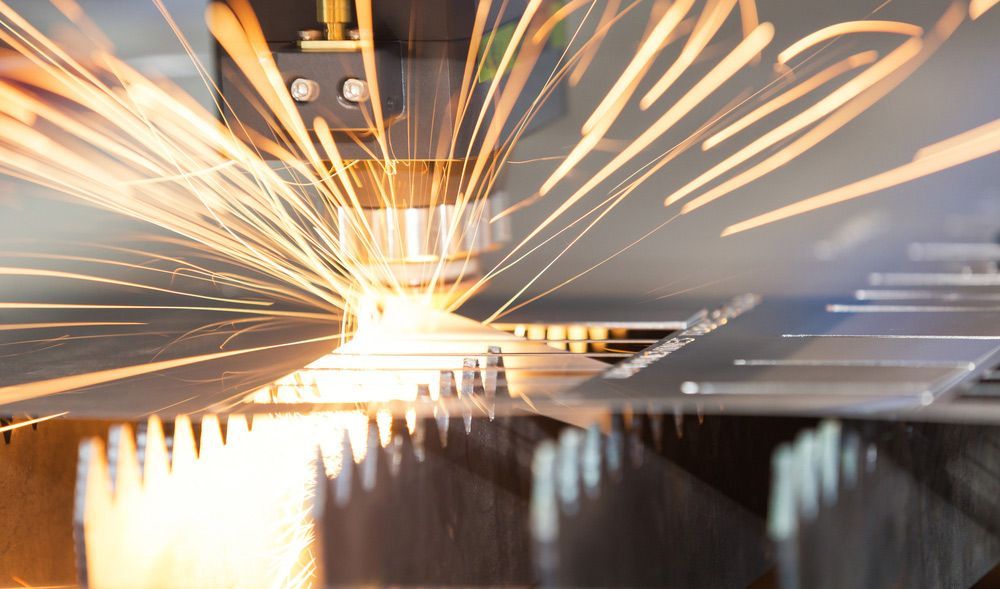

Crafting with Precision

The final step is all about bringing the design to life. Employing state-of-the-art techniques, each product is crafted with meticulous attention to detail. This stage is important in ensuring that what was once a concept becomes a high-quality, tangible product.

Fabrication Techniques: Ensuring Strength and Durability

The strength and durability of a fabricated product are paramount. Various techniques are employed to ensure these qualities:

- Welding: This involves fusing materials together to create a lasting bond. It's not just about joining pieces; it's about ensuring they stay united under all conditions.

- Cutting: Techniques like plasma and oxy-cutting are used for their precision. They allow for the accurate shaping of materials, ensuring each piece fits perfectly in its place.

- Bending: This process involves moulding materials into required shapes while maintaining their structural integrity. It's a delicate balance between form and function.

Sustainability in Fabrication: Eco-Friendly Practices

Sustainability in fabrication is important for both meeting current needs and protecting the future. This commitment is evident in the use of sustainable materials, minimising waste through efficient design and manufacturing and employing energy-efficient methods.

These eco-friendly practices reflect a dedication to responsible and sustainable fabrication, ensuring a positive impact on the environment for generations to come. By embracing these practices, the industry sets a standard for environmental stewardship, contributing to a healthier planet.

Bring Your Project to Life with Agriweld Engineering

At Agriweld Engineering, we understand the unique challenges and opportunities in the fabrication industry. Whether you're facing a complex project or need a bespoke solution, we're here to help. Our team combines expertise with a commitment to quality and sustainability, ensuring that your project is not just completed but excels in every aspect. Let us help you turn your vision into a tangible, lasting reality. Contact us today!