Overcoming Common Challenges In Metal Fabrication For Agricultural Industries

Ever had your farming operations delayed because of fabrication issues? Metal fabrication is essential for keeping equipment efficient and durable, but it has challenges. From weld inconsistencies to material selection, these problems can slow productivity and increase costs. However, these issues can be easily handled with the right tools and expertise. Let’s explore common metal fabrication challenges in agriculture and how to overcome them.

Material Selection: Ensuring Durability & Strength

One of the biggest challenges in metal fabrication is choosing the right materials for agricultural machinery. The equipment needs to withstand heavy use, harsh weather and corrosion. Low-quality or inappropriate materials can result in frequent breakdowns or costly repairs.

Solution: Opt for high-strength, corrosion-resistant metals like stainless steel or galvanised steel, which offer better longevity in agricultural environments. Additionally, collaborating with experts in agricultural engineering can help in selecting the best materials based on specific equipment requirements.

Precision In Customisation: Meeting Unique Agricultural Needs

Every agricultural operation has unique needs, whether it requires specialised machinery for harvesting, seeding or irrigation. A common challenge is ensuring the fabricated parts fit perfectly with the machinery’s design and function.

Solution: Precision is key. Utilising advanced fabrication technology such as CNC (Computer Numerical Control) machining can help create highly accurate parts that meet exact specifications. Working with a fabrication team experienced in agricultural engineering can further ensure the customisation is done right the first time, reducing downtime and increasing efficiency.

Welding Quality: Preventing Structural Weakness

Welding is a critical aspect of metal fabrication, particularly for large-scale machinery used in farming. Poor welding can lead to weak joints, cracks and eventual equipment failure, which are costly in terms of repairs and lost productivity.

Solution: Using state-of-the-art welding techniques like MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding, along with skilled welders, can significantly improve the quality of the welds. Regular inspections for welding integrity should also be part of the maintenance routine to catch any weaknesses early.

Corrosion & Environmental Exposure

Agricultural machinery operates in harsh environments, exposed to moisture, chemicals and extreme temperatures. Rust and corrosion are common issues that can degrade the structural integrity of metal components.

Solution: One effective way to combat corrosion is by applying protective coatings, such as powder coating or galvanisation, to metal surfaces. Additionally, choosing metals with natural corrosion resistance, like stainless steel or aluminium, is another way to ensure long-lasting equipment.

Efficiency In Production: Minimising Downtime

For farmers, time is money. When metal fabrication is delayed, so is the production of essential equipment. This can lead to downtime during critical seasons like planting or harvesting.

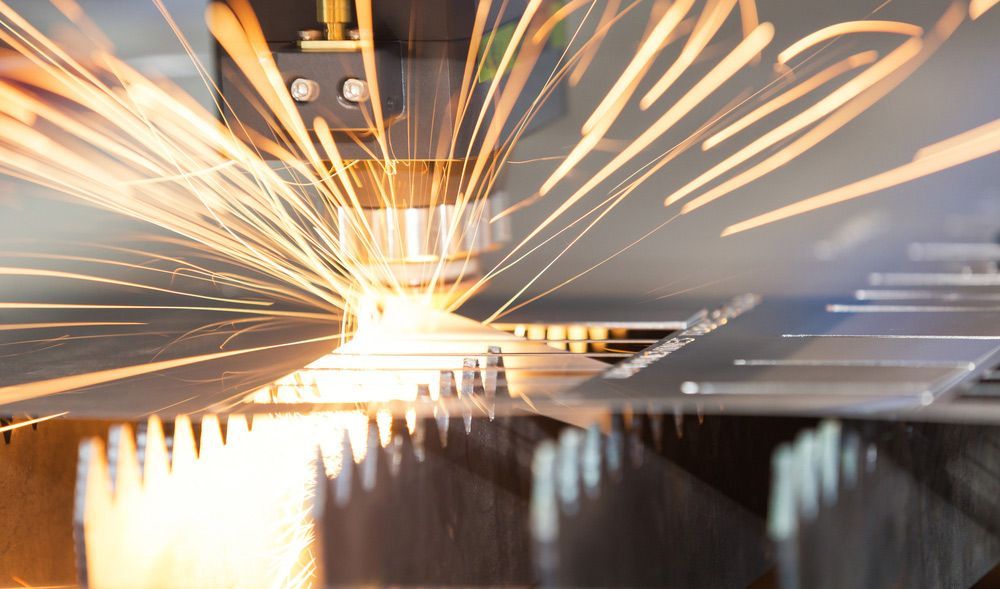

Solution: Partnering with a fabrication company that uses cutting-edge technology ensures faster turnaround times without compromising quality. Automation, laser cutting and computer-aided design (CAD) systems can streamline the fabrication process and ensure the timely delivery of components.

Contact Us For Tailored Metal Fabrication Services

Overcoming common metal fabrication challenges in agriculture requires a combination of the right materials, precise customisation and up-to-date fabrication techniques. At

Agriweld Engineering, we provide high-quality metal fabrication services tailored to the agricultural sector. We use advanced fabrication technology and skilled craftsmanship to help farmers maintain durable and efficient equipment.

Contact us today to discuss how we can support your farming operation with reliable, long-lasting fabrication solutions.